Sold

SOLD - A workhorse that feels like a million dollars!

The following is Gerry's discussion of his new Pro Line Knives (January 30, 2015)

Some of you may recall seeing the Valve prototypes I made a few months back when I was still in a cast. I wanted to get a project rolling that I have been wanting to do for many years, and something you guys will see evolve over time.

McGinnis Pro Line is what we are calling it. I don't want to call it a Mid-Tech, because really the only thing being done outside of our shop is the blade grinding. So, we are going with the McGinnis Pro Line moniker to differentiate these knives from the purely custom side of things. They are all machined using the same processes as my customs, assembled by me the same way with the same attention to detail as I put into my customs, and I have 100% control over how these knives come out because we are doing 95% of it right here in the shop. My dad, 51 years old, is learning and excelling at all the tasks needed to make these knives a reality, and is my partner in McGinnis Pro Line. Two dudes, making knives and having fun!

At this point, I never plan on the multi-hundred blasts of knives going out. For this run of Valves, we are doing a limited number of each in different handle configurations. I just finished up the first variation, the plain rounded handles. Next up is probably some sort of texture that I figure out.

Knives will be sold at shows, and on the forum. We have Miami in April and Blade Show in June coming up. I will try to sell some here on Fridays as well, via lottery.

Care: The only thing you should need to do to your knife upon delivery is clip it in your pocket and carry it. The pivot needs NO ADJUSTMENT. I spend a lot of time tuning each knife, adjusting it won't make anything magical happen. If the stop pin track gets dirty, blow the knife out with compressed air. If you must take it all the way apart, the clip side screw is the screw to take out of the pivot. Be sure to clean and re grease the bearings with Sentry Solutions Hi Slip Grease or equivalent. If you can't figure it out from there, PM me. When in doubt, don't take it apart, especially for no reason.

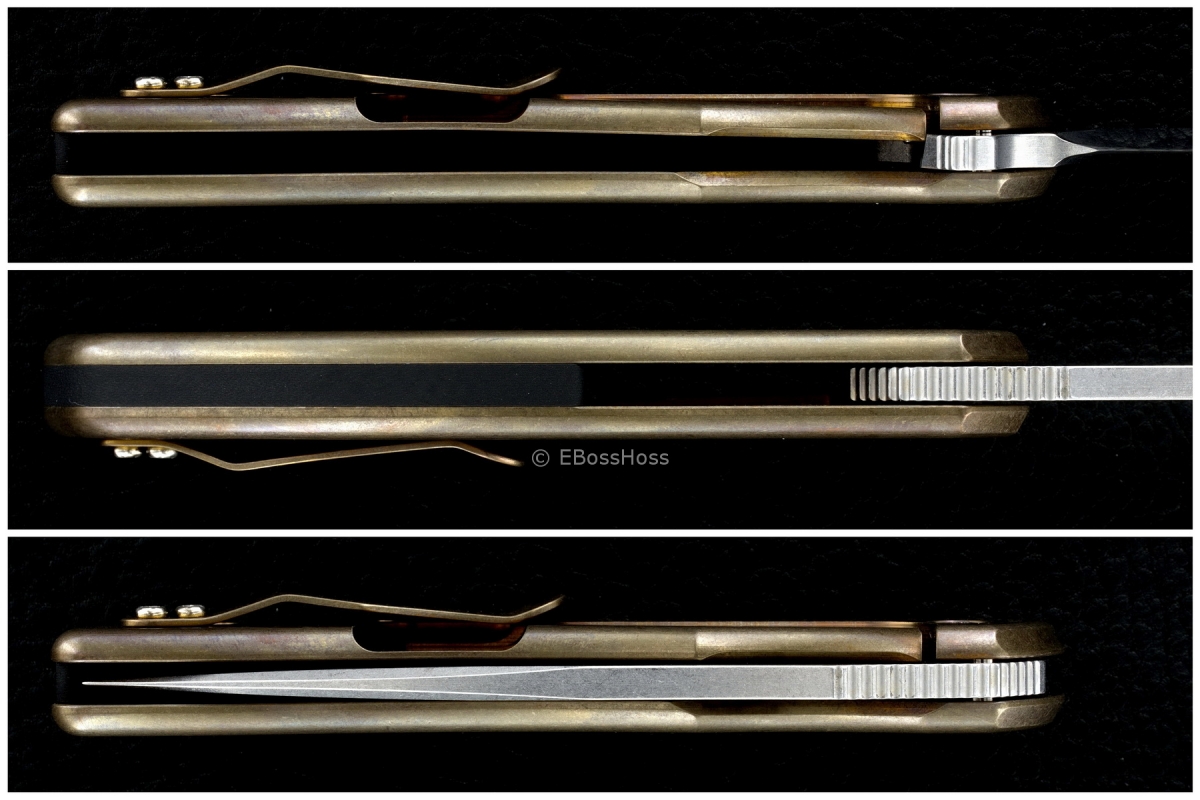

McGinnis Pro Line Valve

- 3.5" blade of flat ground and tumbled .160" CPM154

- .160" 6Al4V Ti frames, .040" Ti clip, G10 backspacer.

- 8 7/16" open, 4 3/4" closed. Blade rides on caged bearings in a formed race in the handles, requiring no pivot adjustment.

And about this one in particular....

- Contoured, Stonewashed, then Annoed Bronze Thick Titanium Handle and Lockbar Side

- Tumbled-finish CPM154 Blade

- Caged Bearing Pivot System

- Black G10 Backstrap

- Matching Bronze Anodized Tip-up Titanium Pocket Clip

- Marked (inside the Lockbar Side) Number "036"

- Perfect Flipping Action, Rock Solid Lock-up, Easy Lock Release

- Specs: 3 5/8" Blade; 8 7/16" OAL; 5.10 Ounces

- Condition: New from Maker

$760